Classification of Areas

When electrical equipment is used in, around, or near an atmosphere that has flammable gases or vapours, flammable liquids, combustible dusts, ignitable fibres or flying, there is always a possibility or risk that a fire or explosion might occur. Those areas of classification are where the possibility or risk of fire or explosion might occur due to an explosive atmosphere and/or mixture is often called a hazardous (or classified) location/area.

Examples of These Areas:

Pharmaceutical & Medical Industry:

- Hospitals

- Clinics

- Veterinary Clinics

Chemical & Finishing Processes:

- Flammable / Chemical Stores & Warehouses

- Laboratories

Petrochemical:

- Filling Stations

- Depots

- Refineries

Agricultural & Manufacturing Plants:

- Silos

- Sawmills

- Manufacturing

Mining & Extractive:

- Gold & Coal Mines

- Process Plants

Oil & Gas:

- Storage Depots

- Utility Installations

- Furnace Installations

Automotive:

- Spray & Paint Booths

- Workshops and Assembly Lines

Hazardous Area Zones

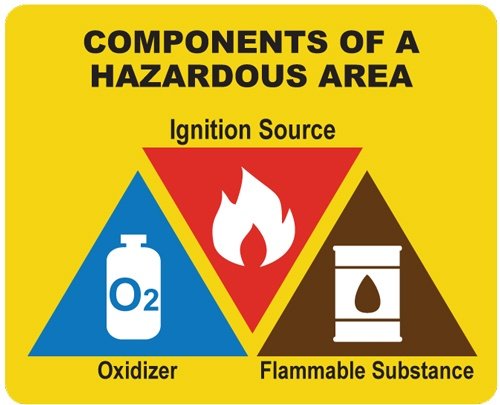

Hazardous Areas are defined by three main criteria

-The type of hazard

-The likelihood of the hazard being present in flammable concentrations

-The (auto) ignition temperature of the hazardous material

The type of hazard (groups)

The hazard will be in the form of gas, vapour, dust or fibre.

The likelihood of the hazard being present in flammable concentrations (Zones)

The likelihood of the hazard being present in flammable concentrations will vary from place to place. A location very close to an open source of hazard will have a high likelihood of a flammable atmosphere. On the other hand, outside a flanged pipe containing a flammable liquid, the likelihood of a flammable atmosphere being present is much lower since it will only occur if the flange leaks. Rather than work with an infinite range of possibilities, three zones are defined

Gases and Vapours

There are three zones for gases and vapours:

Zone 0 Flammable atmosphere highly likely to be present – may be present for long periods or even continuously

Zone 1 Flammable atmosphere possible but unlikely to be present for long periods

Zone 2 Flammable atmosphere unlikely to be present except for short periods of time – typically as a result of a process fault condition.

Zone zero is the most severe zone (the highest probability of flammable atmosphere presence). Equipment for this zone needs to be very well protected against providing a source of ignition.

Dusts

There are three zones for dusts:

Zone 20 Dust cloud likely to be present continuously or for long periods

Zone 21 Dust cloud likely to be present occasionally in normal operation

Zone 22 Dust cloud unlikely to occur in normal operation, but if it does, will only exist for a short period

(The presence of dust layers does not automatically lead to the dust zone. The likelihood of the dust layer being disturbed to create a cloud needs to be considered. Dust layers also need careful consideration in terms of ignition temperature. Because the dust layer can make the equipment under it hotter then normal, a factor of safety is applied to the layer ignition temperature.)

Commercial / Industrial

Contact Us

- South African Government COVID-19 Corona Virus Resource Portal March 29, 2020

- Ministerial determinations propose 13813 MW of new-build by IPPs, none by Eskom March 22, 2020

- Crunch time for South Africa’s national nuclear company, Necsa March 17, 2020

- Dealing with the elephant in the room that is Eskom… March 17, 2020

- Interview with Minerals & Energy Minister Gwede Mantashe February 24, 2020

In the News

In the News

- ECA(SA) POSITION TO BE FILLED: PERSONAL ASSISTANT TO THE NATIONAL DIRECTOR April 17, 2024

- POSITION TO BE FILLED: REGIONAL DIRECTOR/MANAGER April 14, 2024

- APPRENTICESHIP OPPORTUNITY! April 12, 2024

- STREAMLINING ELECTRICAL ADMIN WORK April 9, 2024

- THE TIME HAS COME FOR ALL SA TO GET THE ADVANTAGES OF THE ECA(SA) (watch video here) April 9, 2024